Draft Gear is to reduce the impact force by compressing the elastic element, and absorb the impact energy by friction and damping in the deformation process of the elastic element. Draft Gear has the function of dissipating the impact and vibration between freight cars, so as to reduce the damage to the car body structure and load goods, and improve the stability of train operation.

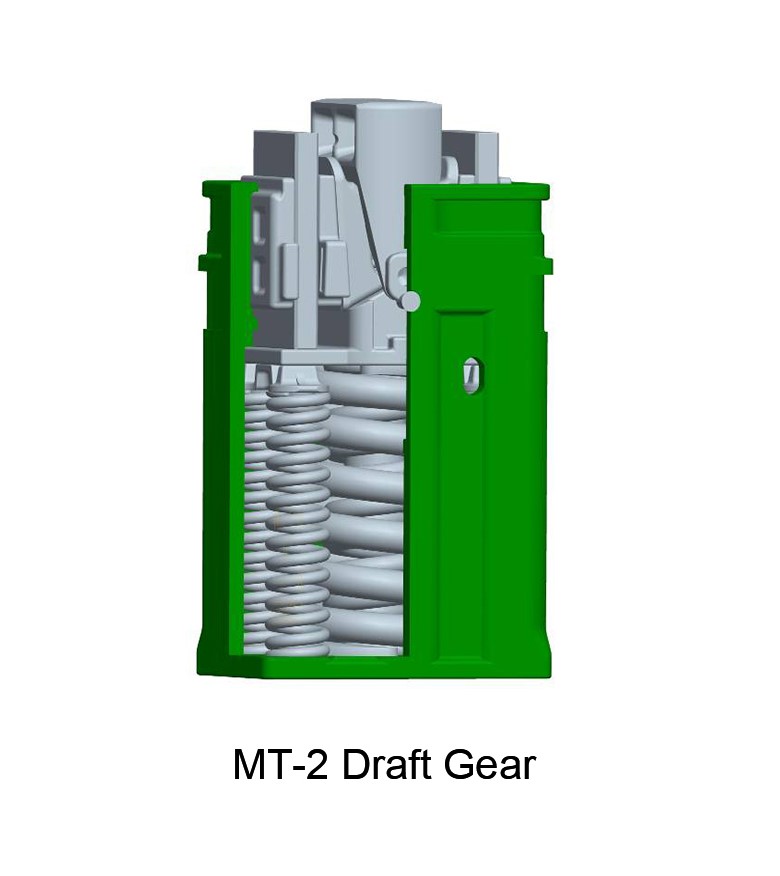

MT-2 Draft Gear

MT-2 Draft Gear has the characteristics of large capacity, low impedance and reliable performance referring to AAR M901E draft gear. It is applied in C63, C76, and C80 series heavy load freight cars. It is also applied in 70t class freight cars in China.

Main Parameters of MT-2 Draft Gear

| Model | Impedance ≤(kN) | Capacity≥(kJ) | Stoke(mm) |

| MT-2 Friction Type Draft Gear | 2270 | 50 | 83 |

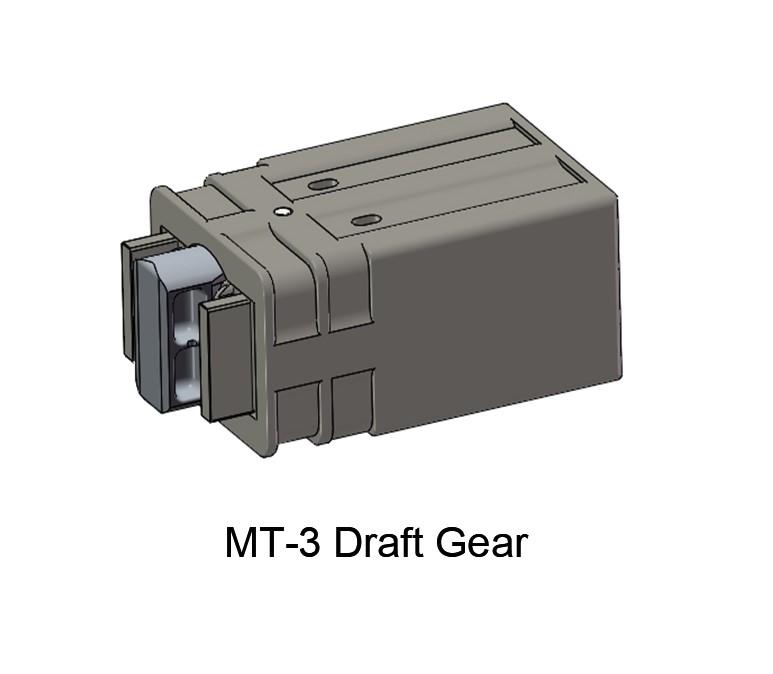

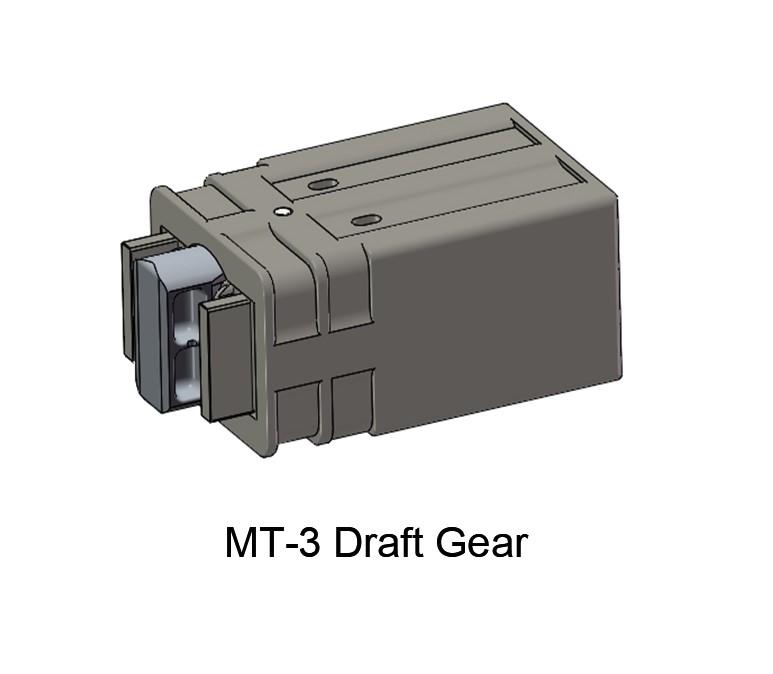

MT-3 Draft Gear

MT-3 type friction draft gear is a kind of all steel dry friction draft gear developed on the basis of absorbing the successful experience of MT-2 type buffer, which can meet the requirements of 60t level general freight cars.

The draft gear is composed of a box body, a friction mechanism and an elastic element. It adopts a friction mechanism with two wedges and two moving plates and a cylindrical spiral spring as the elastic element. The box is not directly involved in the friction effect, and the draft gear is delivered in pre compression state.

MT-3 draft gear has the characteristic of stable performance, low impedance, long service life and easy maintenance.

MT-3 Draft Gear Parameters:

| Model | Impedance≤(KN) | Capacity ≥(KJ) | Stoke(mm) |

| MT-3 Type Draft Gear | 2000 | 45 | 83 |

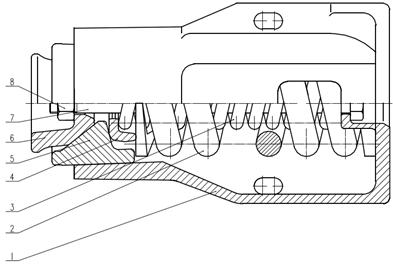

ST Type Draft Gear

ST Draft Gear is friction spring draft gear.

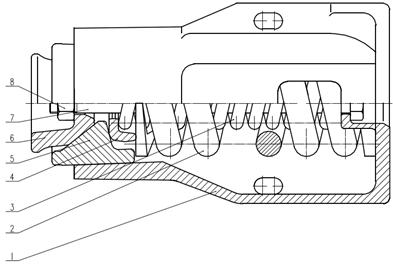

The draft gear consists of friction mechanism, main spring and box. Three friction wedges with the same structure form three friction mechanisms respectively with the thrust cone and the box; the thrust cone bears the impact force from the slave plate, and the friction wedge slides along the slope of the box and the limit washer. The main spring consists of an outer spring and an inner spring. The main spring has a large rigidity. In the process of impact, part of the work done by the impact force is transformed into the elastic potential energy of the main spring of the buffer, and the other part is transformed into the friction work of the friction mechanism. After the impact, part of the elastic potential energy of the main spring is consumed in the friction work produced in the process of friction mechanism recovery, and the rest of the energy is transmitted to the slave plate, so as to alleviate and absorb the longitudinal impact energy.

ST Type Draft Gear Structure as below picture:

Name of each part:

| S/N | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Name | Box | Outer spring | Inner spring | Limit washer | Friction Wedge | Thrust cone | Bolt | Nut M30 |