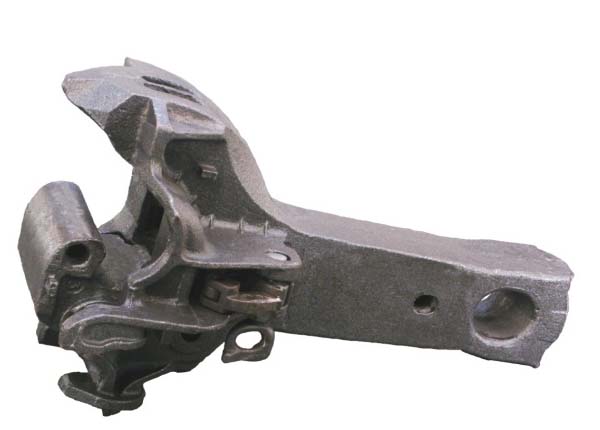

No.16 coupler is designed to meet the requirements of coal transportation lines continuously turnover unload without dismounting the coupler according to AAR S117-67 ‘F Type Interlock coupler profile’.

Main features of No.16 coupler:

1. No.16 coupler could be coupled with 13B coupler, 17 coupler, AAR E coupler, AAR E/F coupler, and AAR F coupler.

2. No.16 coupler is made of high strength low alloy Grade E. The minimum static tensile failure loads of coupler body and coupler knuckle are 4005kN and 3430kN.

3. The free clearance of connected couplers’ profiles is 9.5mm, reducing the longitudinal impact during train running, improving the train’s longitudinal dynamic performance.

4. No.16 couplers comply with TB/T 456 standard.

5. The coupler head is equipped with an interlocking device, which can realize automatic centering interlocking after coupling, reduce the abrasion of coupler body and coupler knuckle, improve the stress state of coupler body and coupler knuckle, and prolong the service lifespan. It could also prevent the coupler separating from vertical direction after coupling; Help to transfer the torsional moment of the tipper, and improve the rotation performance of coupler;

6. The end surface of No.16 coupler is approximately circular, reducing the rotation resistance between coupler body and coupler support seat; the contact surface of coupler yoke and slave plate is spherical, which can rotate 360° around the longitudinal center line of the car body relative to coupler yoke, so that the wagon could be unloaded without disassembling the couplers(only turning the dumper), thus improving the unloading efficiency significantly.

Main Parameters of No.17 coupler:

| Coupler connecting profile | Comply with AAR S117-67 ‘F Type Interlock coupler profile’ or TB/T2950-1999 ‘Interlock coupler connect profile’ |

| Longitudinal movement clearance of coupler connecting profile | 9.5mm |

| Maximum lateral swing angle of coupler | 13° |

| Maximum vertical swing angle of coupler | Upward 5°30’, downward 7° |

| Maximum lateral displacement at coupler connecting line | 167mm |

| Maximum relative angle in horizontal plane | 3°45′ |

| Maximum angle of vertical plane | 2°0′ |

| Allowable height difference of coupler centerline when two couplers are connected | 75mm |

| Coupler body static tensile failure load | ≥4005KN |

| Coupler knuckle Static tensile failure load | ≥3430KN |

| Minimum limit load of coupler yoke (including forging) | ≥4005KN |